The oil and gas market is growing rapidly, as is the use of automation in the industry. The need to increase oil and gas supplies is particularly prevalent in developing regions, in part due to population growth in these regions.

While producing, extracting and refining oil and gas can be complex, automation helps simplify the process. By integrating automated processes, companies can increase productivity, reduce costs, and provide employees with more safety and comfort.

Automation is especially beneficial because oil and gas wells are often located in remote locations where human work is difficult and dangerous.

In the Niger Delta region of Nigeria, environmental leaks, flow control and pipeline temperature control continue to be serious pipeline problems. SCADA (Supervisory Control and Data Acquisition) systems are a proven, cost-effective technology that effectively addresses these issues and is well-suited for widespread acceptance by oil and gas industry operators in the region.

These systems provide early warning, enabling oil and gas operators to take targeted strategic action to prevent or mitigate field damage. For this purpose, a data monitoring system is used – SCADA (Supervisory Control and Data Acquisition).

SCADA (Supervisory Control and Data Acquisition)

IPI Group, a general-purpose technology platform provider customized a highly visible and powerful technology solution leveraging an API data service to enable supply chain professionals to access next-level visibility and get the most accurate IPI Group Limited in Partnership with EMERSON INT. – USA and HUAWEI – China have the requisite professional, technical and personnel competence, to install, rehabilitate, or retrofit SCADA/DCS systems on all the relevant Fields in OML 20.

IPI Solutions Nigeria Limited in Partnership with EMERSON INT. USA is well equipped with both Local and foreign technical professionals with adequate expertise coupled with sound financial capability to handle and execute ICT, AI, Process Control Automation and Optimization projects in the oil and gas industry

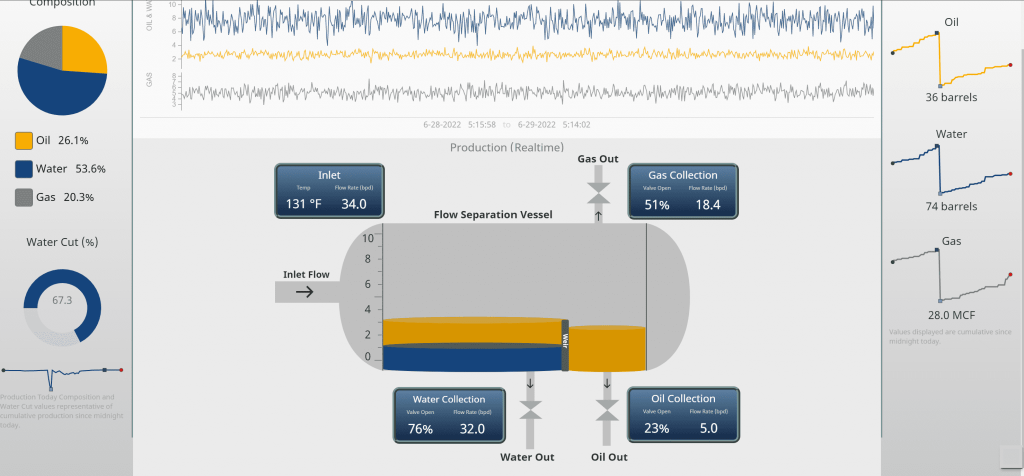

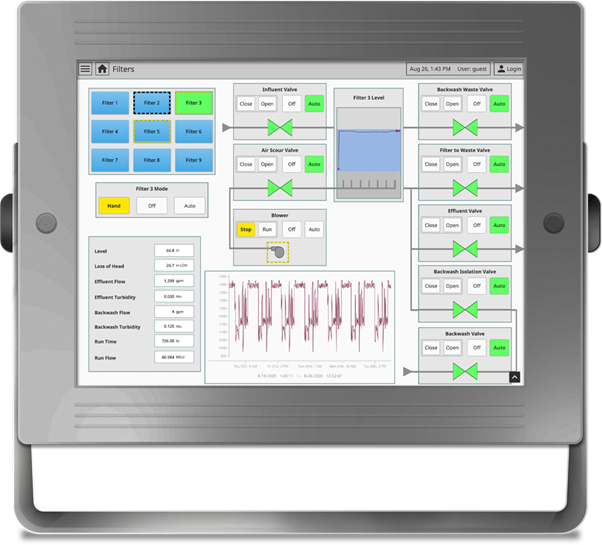

Operations in the oil and gas industry are complex and mistakes are expensive, so it is critical that organizations operating in the sphere make informed and effective decisions. Supervisory Control and Data Acquisition (SCADA) means a set of highly configurable industrial software applications that can be used to support the management of almost any form of the process production. Operators use SCADA systems to perform three critical functions:

- Monitor the physical conditions of the oil field, and provide real-time data of equipment such as sound pressure, oil tank level, and flow.

2. Remotely control processes such as changing operating setpoints, adjusting valve timing, or even performing electronic shutdowns

3. Report on performance metrics, historical trends, and key alerts.

SCADA systems are used by industrial organizations and companies in the public and private sectors to control and maintain efficiency, distribute data for smarter decisions, and communicate system issues to help mitigate downtime.

SCADA systems work well in many different types of enterprises because they can range from simple configurations to large, complex installations.

Virtually anywhere you look in today’s world, there is some type of SCADA system running behind the scenes: maintaining the refrigeration systems at the local supermarket, ensuring production and safety at a refinery, achieving quality standards at a waste water treatment plant, or even tracking your energy use at home, to give a few examples.

ARE YOU INTERESTED IN THIS SERVICE?

Our goal is to ensure that everything we do at IPI, from idea conception, draft, design, implementation and continuous improvement will have Customer Success at the core of our processes